Most vehicles are equipped with the same size tire at every wheel position. Ideally all of these tires should also be of the same type and design, have the same tread depth and be inflated to the pressures specified by the vehicle placard or owner's manual. This combination best retains the handling balance engineered into the vehicle by its manufacturer.

However due to a front-wheel drive vehicle's front tires' responsibility for transmitting acceleration, steering and most of the braking forces, it's normal for them to wear faster than rear tires. Therefore if the tires aren't rotated on a regular basis, tires will typically wear out in pairs rather than in sets. And if the tires aren't rotated at all, it's likely that the rear tires will still have about 1/2 of their original tread depth remaining when the front tires are completely worn out.

Intuition suggests that since the front tires wore out first and because there is still about half of the tread remaining on the rear tires, the new tires should be installed on the front axle. This will provide more wet and wintry traction; and by the time the front tires have worn out for the second time, the rear tires will be worn out, too. However in this case, intuition isn't right...and following it can be downright dangerous.

"When tires are replaced in pairs...the new tires should always be installed on the rear axle and the partially worn tires moved to the front."

When tires are replaced in pairs in situations like these, the new tires should always be installed on the rear axle and the partially worn tires moved to the front. New tires on the rear axle help the driver more easily maintain control on wet roads since deeper treaded tires are better at resisting hydroplaning.

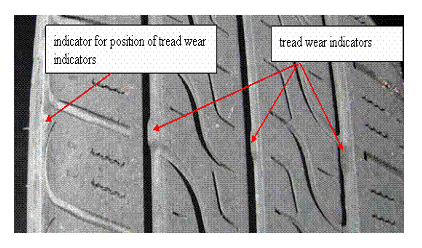

Hydroplaning occurs when the tire cannot process enough water through its tread design to maintain effective contact with the road. In moderate to heavy rain, water can pool up in road ruts, depressions and pockets adjacent to pavement expansion joints. At higher speeds, the standing water often found in these pools challenges a tire's ability to resist hydroplaning.

Exactly when hydroplaning occurs is the result of a combination of elements including water depth, vehicle weight and speed, as well as tire size, air pressure, tread design and tread depth. A lightweight vehicle with wide, worn, underinflated tires in a heavy downpour will hydroplane at lower speeds than a heavyweight vehicle equipped with new, narrow, properly inflated tires in drizzling rain.

If the front tires have significantly less tread depth than the rear tires, the front tires will begin to hydroplane and lose traction on wet roads before the rear tires. While this will cause the vehicle to understeer (the vehicle wants to continue driving straight ahead), understeer is relatively easy to control because releasing the gas pedal will slow the vehicle and help the driver maintain control.

However, if the front tires have significantly more tread depth than the rear tires, the rear tires will begin to hydroplane and lose traction on wet roads before the fronts. This will cause the vehicle to oversteer (the vehicle will want to spin). Oversteer is far more difficult to control and in addition to the initial distress felt when the rear of the car starts sliding, quickly releasing the gas pedal in an attempt to slow down may actually make it more difficult for the driver to regain control, possibly causing a complete spinout.

Experience

Members of Tire Rack team had the chance to experience this phenomenon at Michelin's Laurens Proving Grounds. Participants were allowed to drive around a large radius, wet curve in vehicles fitted with tires of different tread depths -- one vehicle with new tires on the rear and half-worn tires on the front and the other with the new tires in the front and half-worn tires on the rear.

It didn't take long for this hands-on experience to confirm that the "proving grounds" name for the facility was correct. The ability to sense and control predictable understeer with the new tires on the rear and the helplessness in trying to control the surprising oversteer with the new tires on the front was emphatically proven.

And even though our drivers had the advantage of knowing we were going to be challenged to maintain car control, spinouts became common during our laps in the car with the new tires on the front and the worn tires on the rear. Michelin advises us that almost every driver spins out at least once when participating in this demonstration!

Experiencing this phenomenon in the safe, controlled conditions of Michelin's Laurens Proving Grounds rather than in traffic on an Interstate ramp in a rainstorm is definitely preferred!

Recommendations

Tires should be serviced periodically following the rotation patterns provided in the vehicle's owner's manual or as established by the industry to help enhance wear quality and equalize front-to-rear and side-to-side wear rates. The minor differences in tread depth between tires that might be encountered immediately after periodic tire rotations at 5,000-7,500 mile intervals won't upset the vehicle's hydroplaning balance and should not preclude rotating tires. For that matter, any differences in wear rates actually indicate that tire rotations should be done more frequently. Ideally tires should be replaced in complete sets. However when tires are replaced in pairs, the new pair of tires (assuming the vehicle is equipped with the same size tires all of the way around) should always be installed on the rear axle and the existing partially worn tires moved to the front axle.

While insufficient tire rotation intervals and/or out-of-adjustment wheel alignment angles often caused the differences in front-to-rear and side-to-side tire wear rates in the first place, the need to keep deeper treaded tires on the rear axle to resist oversteer conditions caused by wet road hydroplaning is important. Unfortunately this precludes the future possibility of ever rotating tires.

Once a pair of tires has been installed, the only way to escape being forced to drive on mismatched tires continually is to install a complete set of new tires (especially on front-wheel drive vehicles).